eLearning Class

Startup Page

-

Learn how to program the most popular type of metal-cutting CNC equipment!

-

Uses our proven key concepts approach

-

Sixteen activity-packed lessons

-

Narrated presentations - navigate with an easy-to-use media player

-

Printable reading material (over 200 pages)

-

Keep all class materials even after you earn your certificate of completion.

-

A test to take after each lesson - grading is automatic and immediate

-

Many lessons include a programming activity

-

On-going, self-paced course - enroll and begin at any time!

-

Take up to 60 days to finish

-

Personal assistance from your instructor, Mike Lynch

-

A great training value! Enroll today!

What is an eLearning Class?

This is NOT an online class. All files are downloaded to your computer and you can keep them even after you earn your certificate of completion. About 1.5-gb hard drive storage is required.

How it works:

After purchasing this class:

-

We send you a Google Drive link to a .zip file.

-

You download the .zip file and unzip (extract) its folders and files to your hard drive.

-

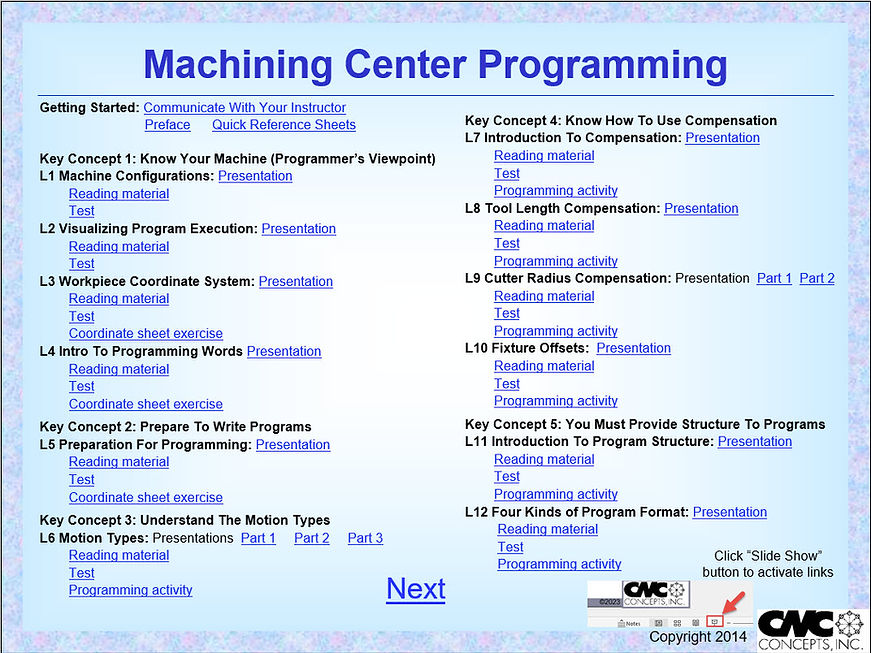

Invoke (double click) the "Startup" file to call up a PowerPoint presentation (shown above) that provides links to all of the class activities (underlined items in the Startup file above are the links). We provide PowerPoint Viewer just in case you do not have PowerPoint installed on your computer.

-

Start the slide show to make the links active.

-

View the presentation and study the reading materials for the lesson.

-

When you're ready, submit the exercise for the lesson (if there is one).

-

When you're ready, take the test for the lesson.

-

Repeat the last three steps for each lesson.

A few more notes about our eLearning classes:

-

Presentations are browser based so you do not need special software to view them.

-

Reading materials are provided in .pdf files.

-

Tests are automatically graded and submitted. You must have an email account and an Internet connection is required.

-

Exercises (coordinate sheet exercises and programming activities) are submitted using the "Communicate with your instructor" activity. You must have an email account and an Internet connection is required.

-

In order to receive a certificate of completion, you must complete all tests and submit all exercises.

Maintaining "active student" status:

-

Your instructor will support you (answering questions and grading tests & exercises) as long as you are an active student. Your purchase of this class includes 60-days of active student status.

-

A 30-day extension can be purchased if you need more time (purchase link can be found at the bottom of this page).

-

While all of the class content is yours to keep, we ignore contact (questions and test & exercise submissions) from inactive students.

-

Active student status can only be achieved by the original student. If multiple students will be taking this class (and expecting instructor assistance), additional purchases of the class must be made.

About the certificate of completion:

-

Students achieving an overall score of 70% or better earn a Certificate of Completion.

-

Students achieving an overall score of 85% or better additionally earn a letter of recommendation.

The Course

This course will help you master what it takes to program a CNC machining center at G code level. We begin in a basic manner - assuming you have no previous CNC programming experience. We do, however, assume you understand basic machining practices as they apply to machining centers. (At the very least, you should have completed the Machining Center Setup and Operation on-line class.) While we begin in a basic manner, we will continue to build upon previously presented information. By the time you’re finished, you’ll know what it takes to program a machining center, and you will have worked on several practice programs.

There are six Key Concepts which are further divided into sixteen lessons:

Key Concept 1: Know your machine from a programmer's viewpoint

-

1: Machine configurations

-

2: Visualizing program execution

-

3: Program zero and the rectangular coordinate system

-

4: Introduction to programming words

Key Concept 2: You must prepare to write programs

-

5: Preparation steps for programming

Key Concept 3: Understand the motion types

-

6: Programming the three most basic motion types

Key Concept 4: Know the compensation types

-

7: Introduction to compensation

-

8: Tool length compensation

-

9: Cutter radius compensation

-

10: Fixture offsets

Key Concept 5: You must provide structure to your CNC programs

-

11: Introduction to program structure

-

12: Four types of program format

Key Concept 6: Special features that help with programming

-

13: Hole-machining canned cycles

-

14: Working with subprograms

-

15: Other special programming features

-

16: Programming rotary devices

Each lesson includes a presentation, reading material, and a test that will be graded. Many lessons include assignments as well (coordinate sheet exercises and programming activities). If you have questions during a lesson, answers are just an email away.

When you complete this class, you'll know what it takes to program a CNC machining center at G code level. While you will still need hands-on practice with an actual machine (practice you'll get from your employer), you will understand the concepts needed to program a machine.

Qualify for the student price for NCPlot

NCPlot is a great tool path verification tool. I use it to grade the programming activities done in this class. If you register for this class, you'll be eligible to purchase NCPlot for the student price ($99.00).

Though it is not a requirement for taking this class, NCPlot is a very helpful programmer's tool. With NCPlot, you will be able to see the tool path for programs you work on during this class.

Pricing: